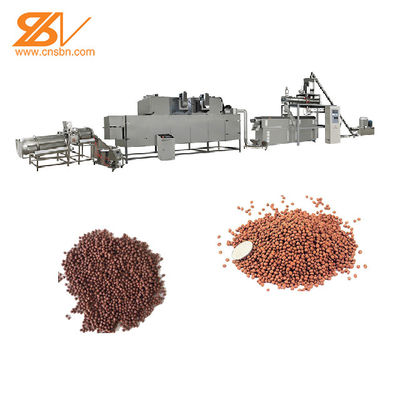

사료 관리가 편리하며, 수생 압출 사료는 오랫동안 수면에 떠 있을 수 있습니다.

사료를 줄 때 사료 테이블을 설치할 필요가 없으며, 정해진 지점에서 사료를 주는 것만으로 충분합니다. 물고기는 먹을 때 물 표면으로 떠올라야 하므로

물고기의 먹는 상황을 직접 관찰하고, 사료량을 적시에 조절하며, 물고기의 성장과 건강을 적시에 이해할 수 있습니다. 따라서 수생 압출 사료의 사용은

과학적인 사료 공급 및 관리에 도움이 되며, 이는 많은 시간을 절약할 뿐만 아니라 노동 생산성을 향상시킵니다.

사육자는 사육되는 물고기의 종, 사양, 수량, 수온 및 사료 비율에 따라 먹이를 줘야 하는 양을 계산하고, 빠르게 먹이를 줄 수 있으며, 이는 많은 시간을 절약할 뿐만 아니라

노동 생산성을 향상시킵니다.

질병 발생을 줄이기 위해 사료 재료에는 호기성 유기체, 호중구, 대장균, 곰팡이 및 살모넬라와 같은 유해 미생물이 포함되는 경우가 많습니다. 동물 사료 재료의 함량이 비교적 높습니다. 팽창의 고온, 고습도 및 고압은 대부분의 유해 미생물을 죽일 수 있습니다. 데이터에 따르면, 그램당 대장균 수는 최대 10,000개이며, 팽창 후에는 10개 미만으로 남습니다. 살모넬라는 85℃ 이상의 고온에서 팽창 후 기본적으로 죽일 수 있으며, 이는 수질을 유지하고 양식의 불리한 환경 요인을 줄이는 데 도움이 됩니다. 동시에 0.4에 도달하며, 이는 수분 함량 8%-10%와 동일하며, 이는 사료의 저장 안정성을 더 잘 향상시킬 수 있습니다.

9. 팽화 및 부유 팽화 사료와 분말 재료 및 과립 재료의 활용률 비교

압출 부유 어류 사료는 사료 활용도를 향상시키는 데 도움이 됩니다. 고온 및 고압 처리로 인해

조건에서 사료의 전분이 숙성되고 지방 등이 소화 및 흡수에 더 도움이 되며, 섬유 구조

및 세포벽이 파괴되고 연화되며, 면실박의 고시폴과 콩의 트립신 억제제 및 기타

유해 물질이 파괴되어 사료의 기호성과 소화성을 향상시킵니다.

또한, 압출 과정의 물리적 및 화학적 변화로 인해 압출 사료는 일반적으로 1% 이내의 분말을 생성하며, 이는 사료의 효과적인 활용도를 직접적으로 향상시킵니다. 일반적으로 압출 부유

사료를 사용하여 물고기를 키우면 분말 사료 또는 기타 펠릿 사료에 비해 사료를 5-10% 절약할 수 있습니다.

10.

저희 서비스

1).

OEM & ODM

2).One 년 보증 및 평생 유지 보수 서비스.

3). 판매 전, 판매 중 및 판매 후 컨설팅 서비스.

4). 프로젝트 계획 및 설계 서비스.

5). 모든 기기가 작동할 때까지 기기 디버깅.

6). 고객에게 기기를 올바르게 작동하고 유지 관리하는 방법을 교육합니다.

7). 적시에 새로운 제품 기술 및 레시피를 제공합니다.

11. 회사 정보:Jinan Saibainuo Technology Development Co., Ltd.

는 16년 이상의 경험을 바탕으로 장비 연구, 개발, 생산, 판매 및 서비스를 통합하는 종합 기업입니다.지속적인 노력을 통해

이미 팽화 식품 가공 라인, 분리 대두 단백질 가공 라인 및 실험실 압출기 등과 같은 여러 시리즈의 성숙한 생산을 소유하고 있습니다.

12.포장 및 운송:포장: 텍스처 압출 대두 덩어리 제조 기계용 내부 비닐 봉투, 외부 나무 케이스 (고객의 필요에 따라 나무 케이스 또는 나무 펠릿 등을 채택).

운송: 고객의 요구에 따라 배송, 기차, 특급 또는.

11.FAQQ: 당신은 무역 회사입니까, 아니면 제조업체입니까?

A: 저희는 제조업체입니다. 저희 공장에 오셔서 기계를 방문하고 확인해 주십시오.

Q: 배송 시간은 얼마나 됩니까?

A: 일반적으로 재고가 있는 경우 5-10일입니다. 또는 재고가 없는 경우 20-35일이며, 수량에 따라 다릅니다.

Q: 샘플을 제공합니까? 무료입니까, 아니면 추가입니까?

A: 예, 샘플을 무료로 제공할 수 있지만 운송 비용은 지불하지 않습니다.

Q: 지불 조건은 무엇입니까?

A: 30% T/T 선불, 선적 전 잔액.

Q: 애프터 서비스는 어떻습니까?

A: 구매자 공장에 엔지니어 1명을 보내 10일 동안 운영자에게 설치 및 교육을 제공합니다.

Q: 구매자에게 수식을 제공합니까?

A: 예, 구매자에게 수식을 제공합니다.

저희 제품에 관심이 있으시면 언제든지 문의해 주십시오.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!